Comprehensive breakdown of SENSURE Solutions: Key Components and Technologies

NEWS / 14 February 2025

Since 2010, with over 150 installations worldwide, SENSURE has been providing AI-based in-line and off-line vision inspection systems powered by self-learning technology (click here for more details) and AI-driven product and process data analytics tools.

SENSURE can provide, even on already existing lines:

- SENSURE SYNAPSE Software suite and Vision Material for Integration into processing or packaging equipment, as well as robotic stations

- Ready-to-use Turnkey Solutions (SENSURE STARGATE), including any necessary modifications to the end customer's production line

Let's delve into the key components of SENSURE's solutions in detail:

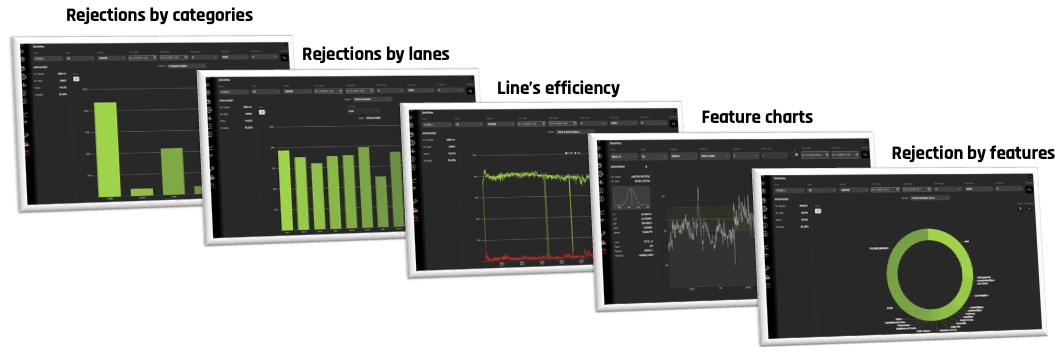

- SENSURE SYNAPSE Software Suite, a comprehensive solution for measurement, defect detection, and classification, supporting external data integration, PLC/Robot communication, SQL storage, web-based visualization, and advanced data analytics tools, including statistical charts with customizable timeframes and filters for detailed production and defect detection analysis. The system is accessible through an innovative web-based Graphical User Interface (GUI) with a user-friendly and intuitive layout for seamless interaction with vision inspection systems.

- Tools that support the team in process improvement activities. Specifically, the Smart Alert System provides operational recommendations and real-time visualization of corrective actions based on historical data analysis or cause-and-effect diagrams. Additionally, tools support production and process optimization and automation with closed-loop control, reducing the need for manual interventions (for example, automatic feedback control of oven temperatures, etc.).

- Vision hardware operates in both the visible and non-visible spectrum, with dedicated optics and a lighting source to ensure proper product illumination. In this context, vision technologies can range from 2D linear or matrix cameras to 3D laser profilometers, SWIR cameras for moisture analysis, thermal cameras, and more.

- Processing units, responsible for running the SENSURE Software Suite.

- Live dashboards along the line with products/process information.

- Mechanical frame, conveyors, rejection mechanism (click here for more details), etc.

- The expertise in vision systems and data analysis of SENSURE's team.