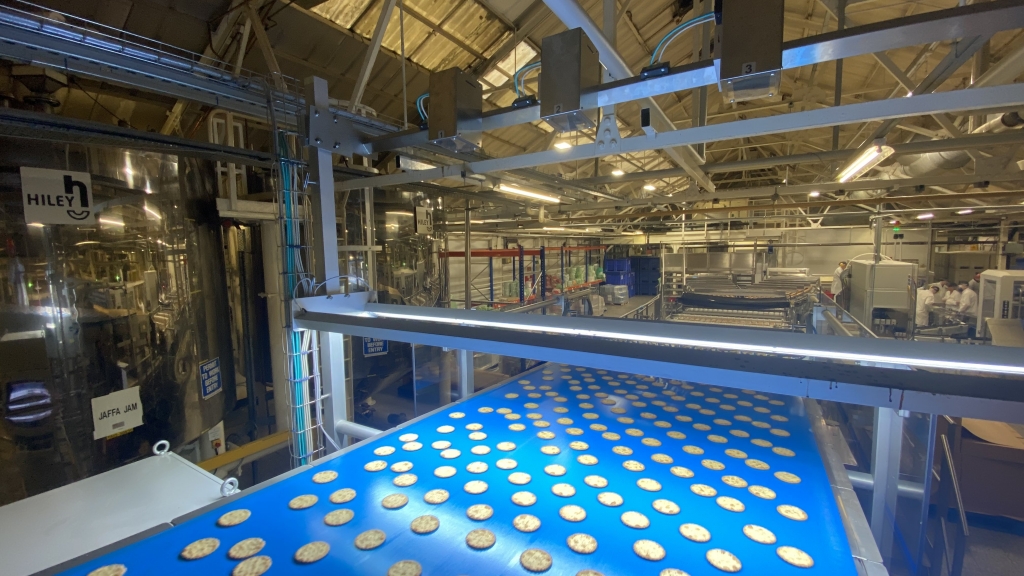

Ensuring crackers quality and improve the production process with SENSURE solutions

Let's travel back in time to the early 1800s when crackers made their flavourful debut. Since then, these crispy delights have delighted snack lovers worldwide. These versatile baked snacks, loved for their crispiness and endless toppings, are the perfect companion for any occasion.

SENSURE offers a wide range of advanced technologies that help crackers (and other similar baked products like biscuits, rusks, etc.) producers optimize their production processes and maintain the highest levels of product quality. The SENSURE vision inspection systems enable the identification of defects, even at high speeds, using various technologies such as 2D cameras, 3D laser profilometers, and SWIR cameras for moisture analysis. Non-compliant products are automatically rejected using different technologies (air nozzles, traps, retractable belts, etc.) depending on products dimensions, line speed, etc.

Below are some of the defects that can be identified on crackers by SENSURE vision insepction systems:

- Colour (overbaked/underbaked)

- Spots detection (top/bottom parts of the products)

- Shape/Size/Products breaks

- Topping conformity/distribution

- Inclusions

- Thickness

- Moisture

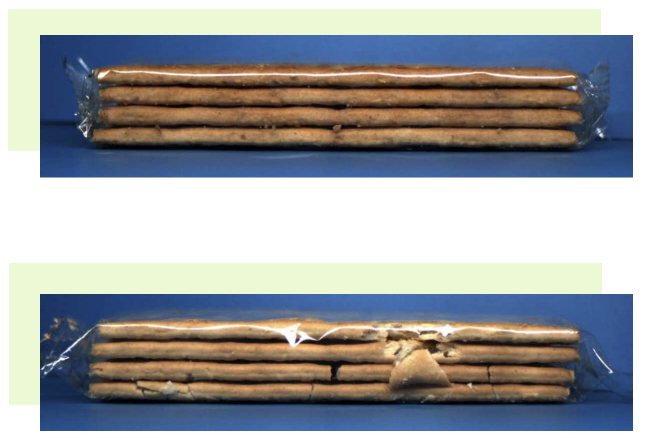

With SENSURE vision inspection systems, it is also possible to control the number and integrity of crackers inside transparent packages.

With SENSURE's process and product data analytics tools, it is possible to provide:

- Instant feedback for operators on optimized dashboards, enhancing real-time decision-making and operational efficiency

- Smart Alert System, giving operational recommendations and real-time visualization of corrective actions based on historical data analysis or cause-and-effect diagrams

- Production and Process Optimization and Automation with closed-loop control, reducing the need for manual interventions

Download the application overview datasheet clicking on the picture here below