SENSURE Software Suite

powered by

SYNAPSE

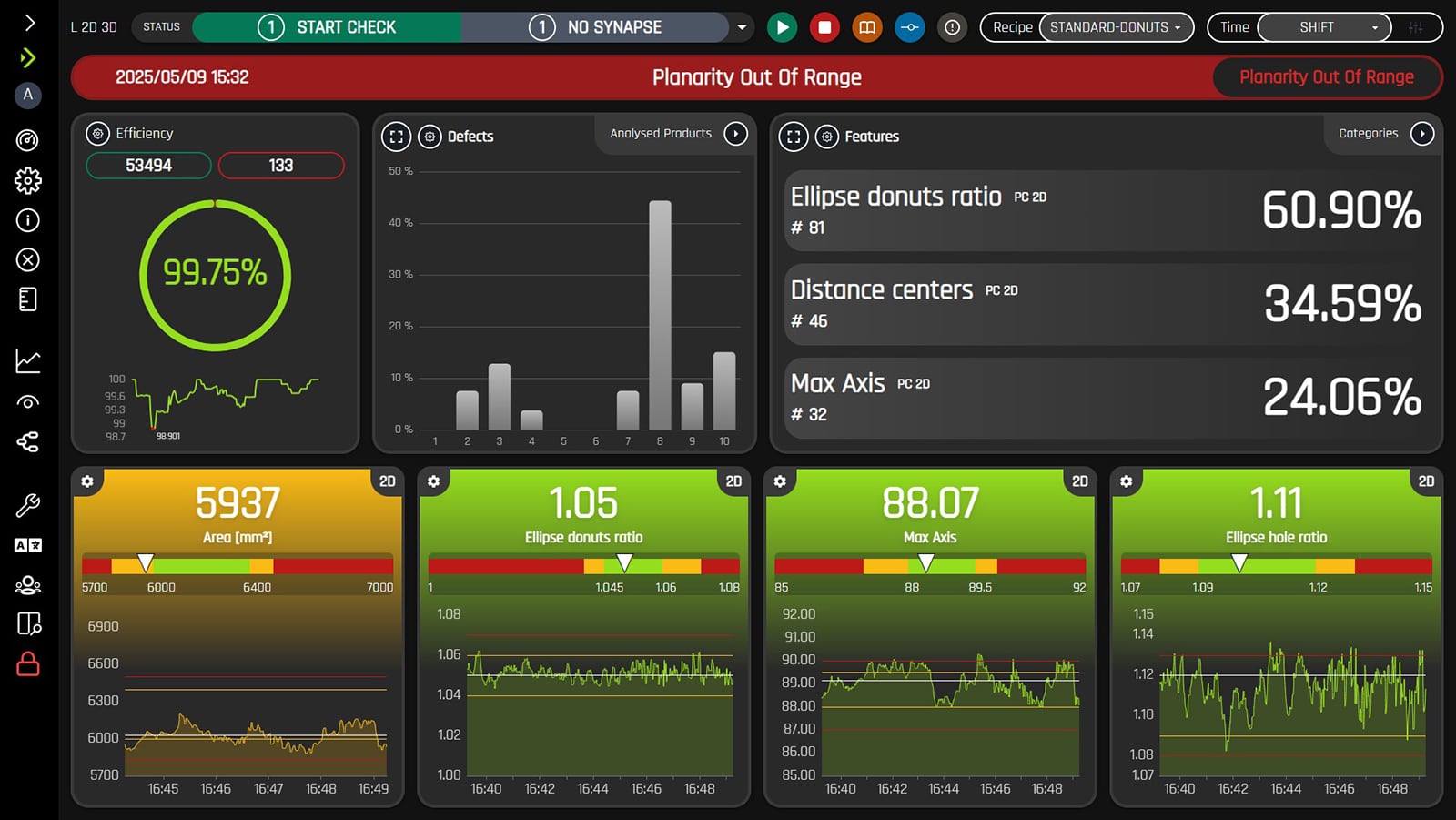

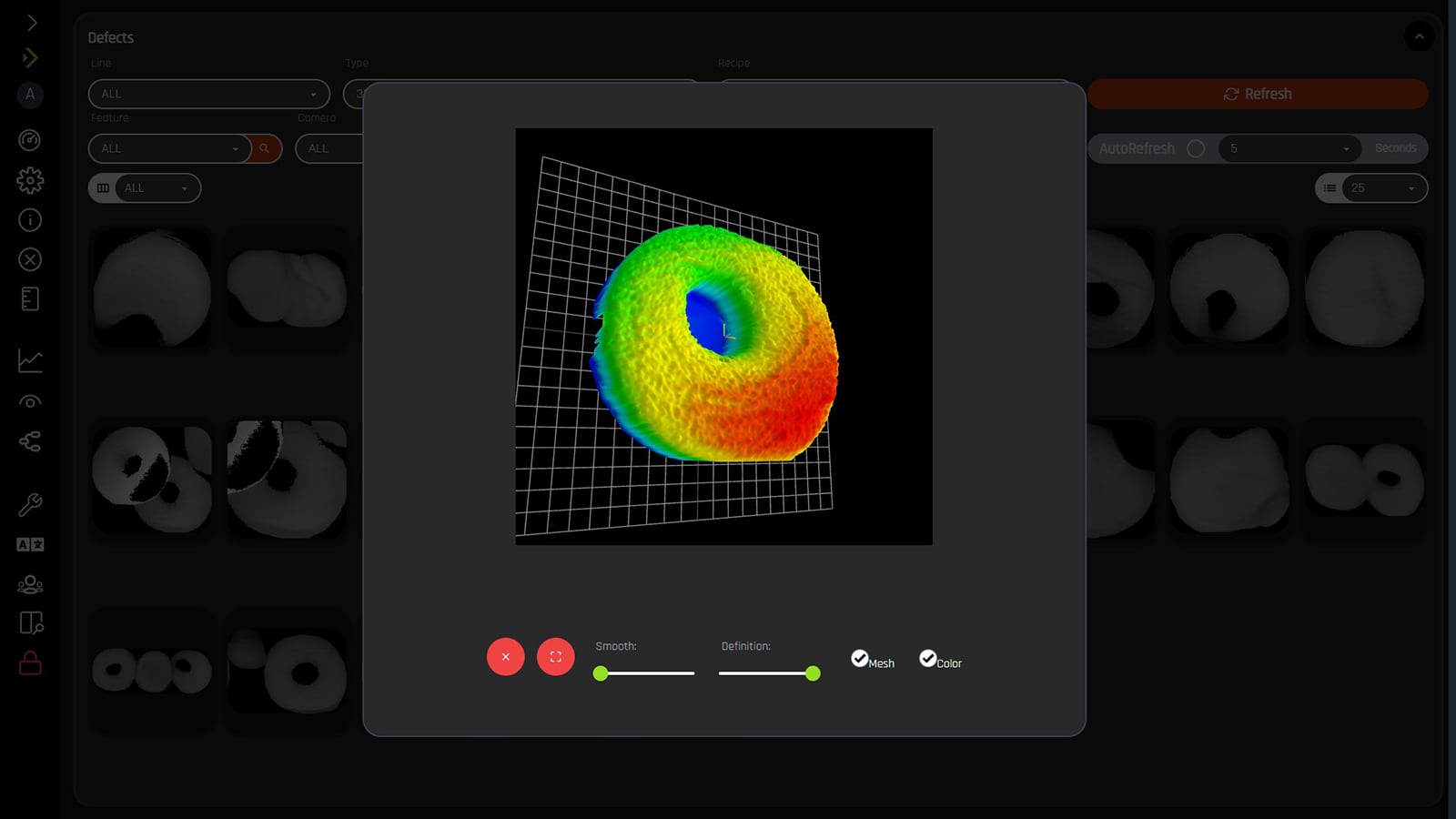

SENSURE Software Suite (powered by SYNAPSE, expandable with DATAVIEW and DATAMIND optional modules) is an AI-powered comprehensive solution for measurement, defect detection, and classification, supporting external data integration from machinery and IIoT devices, PLC/Robot communication, SQL storage, web-based visualization, and advanced data analytics tools for process improvement.