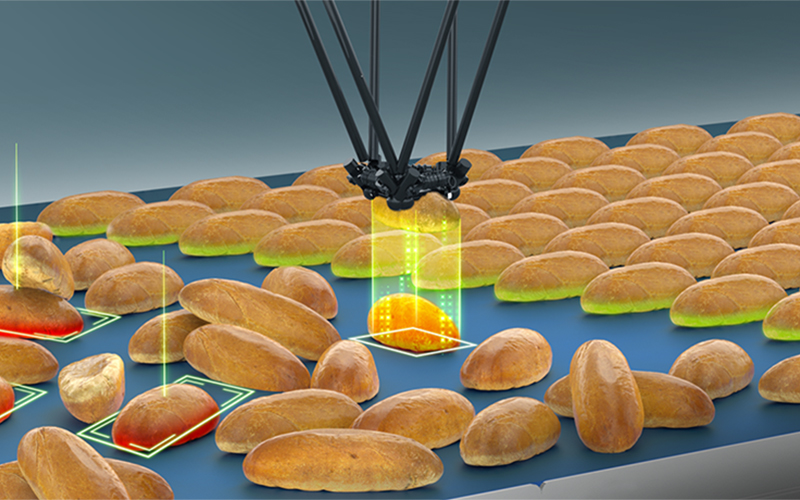

PRODUCT AND QUALITY INFORMATION COMMUNICATION TO ROBOTS/PLC FOR PICK-AND-PLACE OPERATIONS

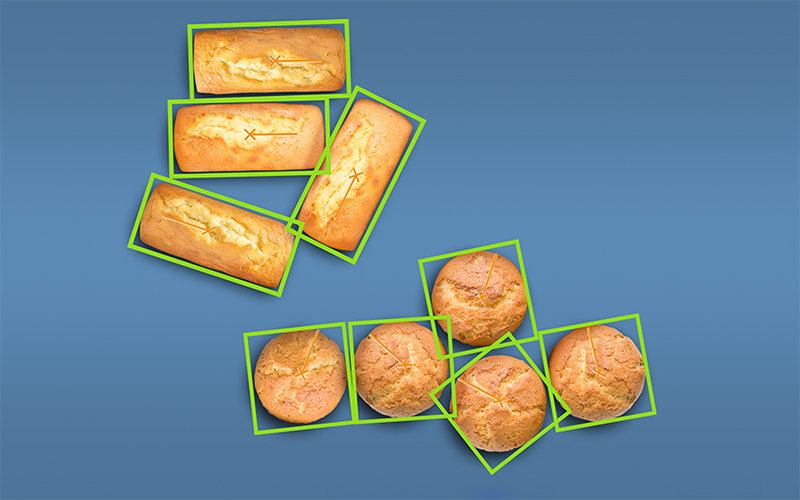

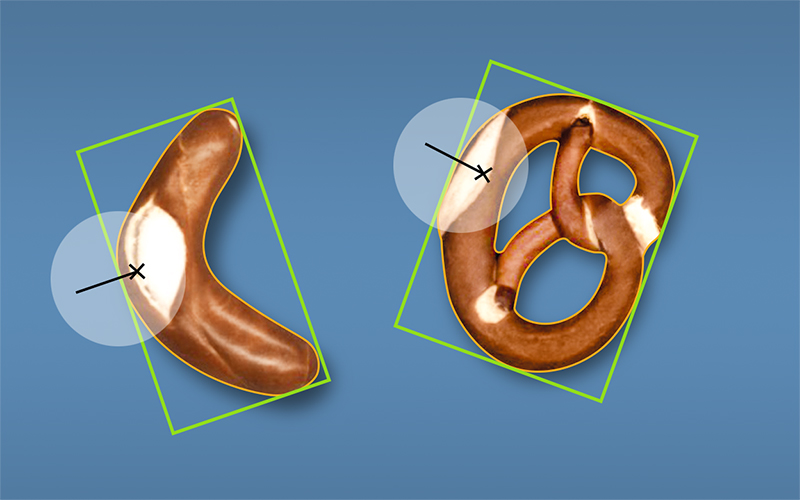

SENSURE SYNAPSE can locate the center of mass (X, Y, Z coordinates) and orientation of a product, transferring this information to a robot while also communicating quality data for automatic sorting.