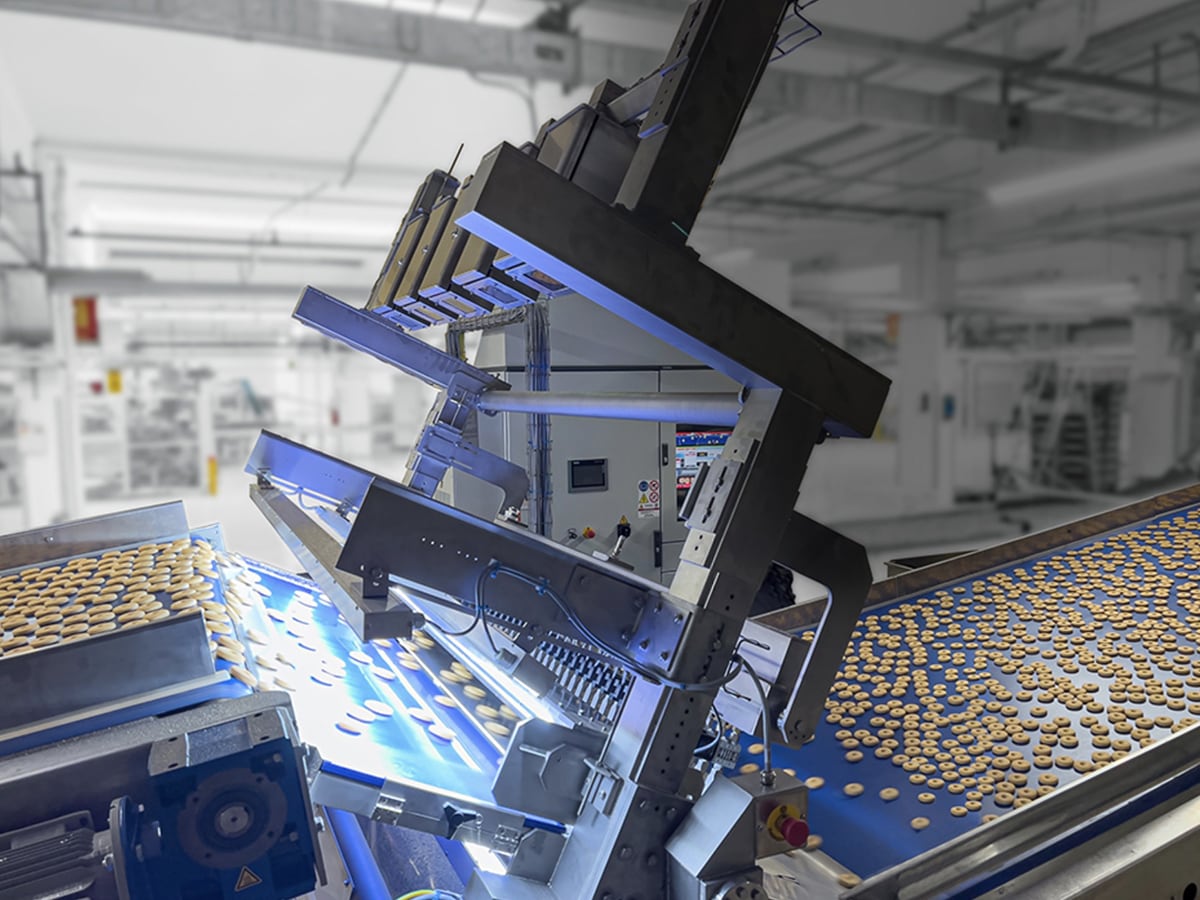

In industries where product variability is high, such as in the food production sector, Artificial Intelligence can play a significant role in quality control.

The many variables that can impact a production line, such as oven drifts, ambient light fluctuations, raw material variations, recipe inconsistencies, and conveyor belt cleanliness, make it challenging to establish accurate analysis thresholds.

SENSURE SYNAPSE QUALITY utilises Artificial Intelligence algorithms and self-learning approach to classify products as compliant or non-compliant and identify defects and irregularities.

As a result of these technologies, SENSURE SYNAPSE QUALITY provides best-in-class quality control with a system that can automatically select features to be controlled in products and optimise tolerances for controlled measurements.

This approach eliminates the complex setup process that is typically associated with traditional systems, making installation and setup fast and straightforward due to the self-learning ability of SENSURE SYNAPSE QUALITY.